Indoor equipment

Total control over accuracy

Here the specifications of your project come to life

without compromise.

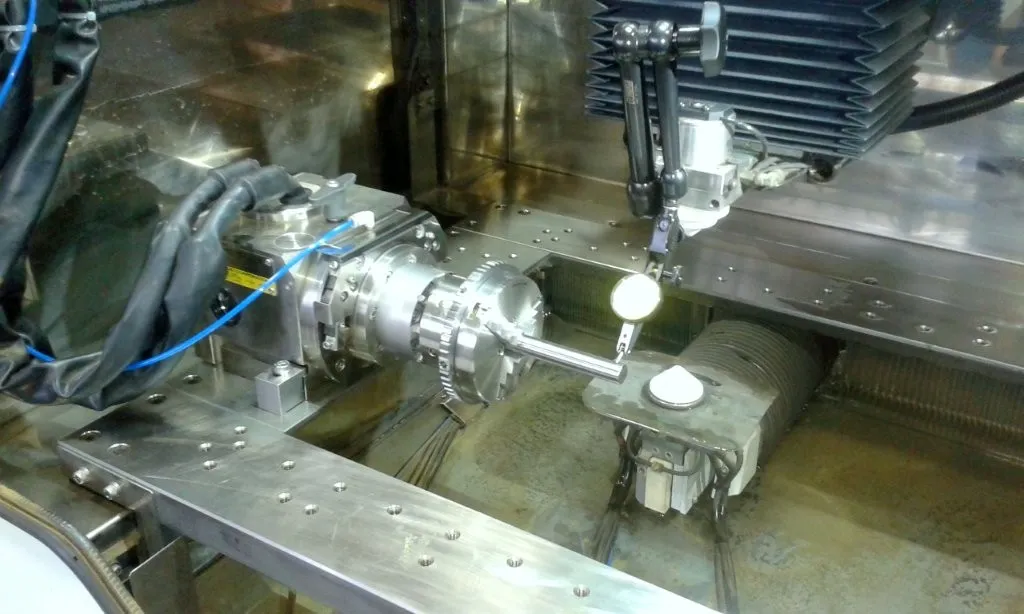

Thein-house tooling shop is the real beating heart of F.B.M., the place where ideas take shape and precision becomes a given.

Here, our decades of experience blends with the latest CNC technology, ensuring total control over every stage of mold and toolingconstruction.

Havingin-house tooling means offering our B2B partners an invaluable competitive advantage:

Precision

Thanks to advanced CNC machine tools (up to 3 continuous axes), every mold and tooling is made with minimal tolerances, ensuring the highest quality from the design stage.

Flexibility and speed

We manage the entire process in-house, from mold design to production. This allows us to reduce development time, optimize changes, and respond with agility to specific needs, even in the case of prototyping or complex customizations.

Quality Control

every stage of manufacturing is monitored by our team of technical experts, ensuring that the die ortooling exactly reflects your specifications and our rigorous quality standards. This results in cold stamping and metal stamping of the highest standard.

Integration between our engineering department and tooling allows us to start directly from your design to make molds and tooling tailored to the part you need.

We use only certified materials to give you the assurance of a reliable, high-performanceend product.